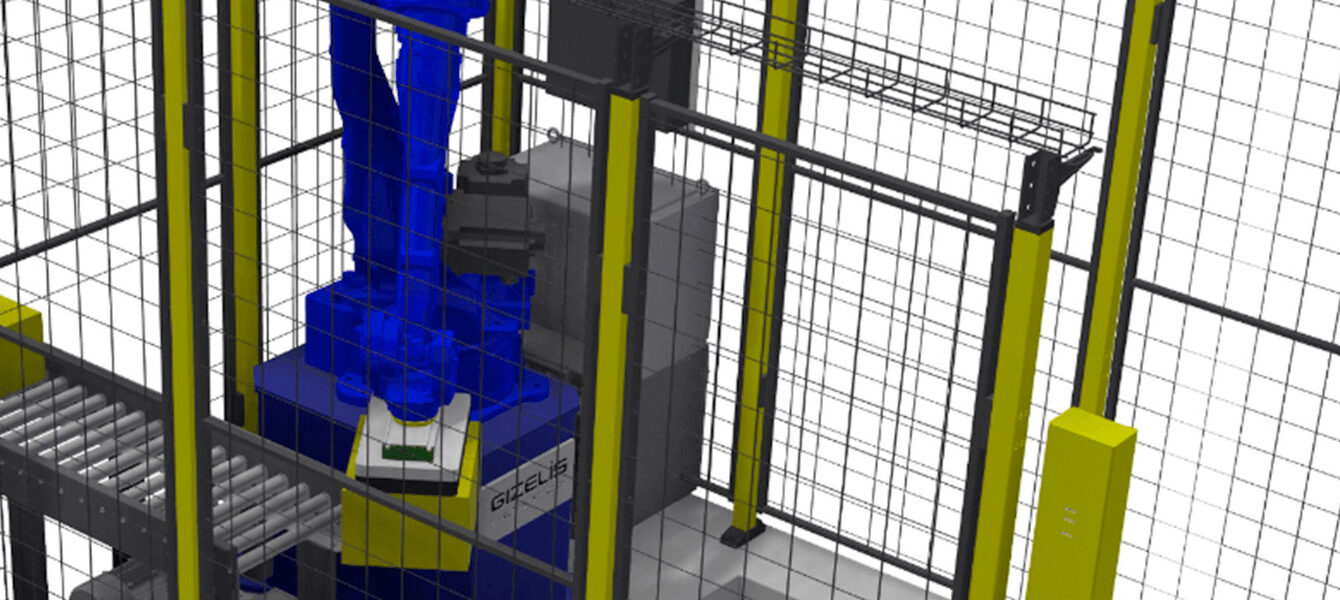

Automated Palletizing for Small to Medium Operations

The Cell Pal Boxy© by Gizelis Robotics is a compact, single-pallet palletizing cell, designed to maximize efficiency while minimizing floor space requirements. Featuring a standard attached conveyor and a user-friendly load/unload system, this solution ensures seamless palletizing with a forklift or pallet jack.

Key Advantages of Cell Pal Boxy©

User-friendly operation with quick start-up cycles.

Low maintenance, ensuring long-term reliability.

Cost-effective solution for automated palletizing.

Small footprint, maximizing workspace efficiency.

Advanced reliability for continuous operation.

Industry Applications

- Food Processing

- Pharmaceuticals

- Chemicals

- Manufacturing

- Small Breweries

- Plastic Packaging

Optional Equipment & Features

- Mechanical or electrical gripper for different applications.

- Parametric programming for customizable palletizing patterns.

- Energy-saving technology for optimized power consumption.

Key Features of Cell Pal Boxy©

Compact, Space-Saving Design

Minimal footprint, making it ideal for small to medium production environments. Cell dimensions: 2700 x 2380 x 2500 mm

____________________

Reliable & Flexible Performance

Utilizes a flexible vacuum gripper for top-picking boxes. Max pallet height: 1800 mm. Meets EN ISO 13849 Category IV safety standards

____________________

High-Capacity Palletizing

Handles boxes up to 50 kg Processes up to 10 cycles per minute (CPM). Supports pallet sizes: 1200 x 1000 mm (UK), 1200 x 800 mm (Euro pallet)

____________________

Versatile Robotics.

Limitless Possibilities.

Application Uses

Precision and Productivity with Robotic Welding

Precision and Productivity with Robotic Welding

Welding is one of the most fundamental applications of industrial robotics, offering unmatched precision, speed, and consistency. With the increasing difficulty of finding skilled welders, due to the hazardous nature of the process, including high radiation and gas emissions, robotic welding provides a safe, reliable, and efficient alternative.

The Role of Robotics in Welding

Industrial robots eliminate the risks associated with manual welding by taking on the most demanding and dangerous tasks. They ceaselessly and tirelessly execute welding processes, ensuring that every weld meets the required quality standards. Their steady motion and high precision deliver faultless, repeatable results, making them essential for high-quality end products.

Advanced Robotic Welding Capabilities

Gizelis Robotics offers cutting-edge robotic welding solutions that enhance manufacturing efficiency, including:

- Real-Time Machine-Robot Communication

- Robots integrate with MIG/MAG and TIG welding machines, adjusting parameters in real-time for optimal results.

- Automated Wire Feeder

- Ensures consistent feeding, improving welding precision and quality.

- Welding Pincer & Automatic Pincer Cleaner

- Maintains high-quality welding output even after extended hours of operation.

- Shock Sensors for Collision Prevention

- Stops the robot instantly in case of accidental contact with another object.

- External Axes Manipulation

- Expands the robot’s work envelope, allowing welding of complex and hard-to-reach areas.

- Positioners for Enhanced Flexibility

- Boosts system agility and productivity, accommodating various welding tasks.

- Special Sensors for Path Control

- Adjusts welding path variations, crucial for large-scale components.

- Customizable Waving Templates

- Reduces the number of filler sessions, optimizing efficiency and ensuring superior welding results.

Innovating Welding with Robotics

By integrating advanced robotic welding technology, Gizelis Robotics delivers unparalleled precision, safety, and productivity, providing manufacturers with high-quality results across various applications.

Maximizing Productivity with Robotic Handling

Maximizing Productivity with Robotic Handling

Industrial robots play a crucial role in standardized and repetitive processes, significantly enhancing productivity, precision, and operational efficiency. From press-brakes and plastic or metal molding to CNC feeding and product re-orientation, robotic handling optimizes performance, eliminates downtime, and ensures product consistency.

The Role of Robotics in Material Handling

Automation in handling applications offers a significant advantage over manual labor, ensuring high-precision product placement and seamless operation across various industrial processes. Robots eliminate machine downtime and deliver consistent quality in handling tasks.

One of the key benefits of robotic handling is its ability to operate in cleanroom environments, ensuring contamination-free processing. Unlike human labor, robots can handle products without the risk of bacterial infection, reducing the need for sterilization and lowering production costs.

Flexible and Seamless Integration

Gizelis Robotics provides cutting-edge robotic handling solutions that offer:

- High-Precision Product Placement

- Ensuring consistent quality and accuracy in production.

- Machine Downtime Elimination

- Increasing efficiency and reliability in industrial operations.

- Cleanroom Compatibility

- Reducing contamination risks and sterilization costs.

- Robotic Flexibility

- Adapting to various industrial tasks with seamless integration into existing machinery.

Enhancing Industrial Handling with Robotics

With unmatched flexibility and efficiency, Gizelis Robotics delivers innovative robotic handling solutions that optimize automation, reduce costs and elevate production standards.

Automating Palletizing for Maximum Productivity

Automating Palletizing for Maximum Productivity

Palletizing and unpalletizing procedures are highly recommended for robotic automation, offering exceptional speed, precision, and flexibility. With capabilities for handling large payloads (up to 1300kg), extended operating radius (3200mm), and high-speed operations, robotic palletizing is an essential part of modern manufacturing units.

The Role of Robotics in Palletizing

Regardless of the material type, sacks, cartons, tins, or bottles, robotic arms perform pick-and-place operations with an accuracy of ≤0.25mm. Specially designed grippers (manipulator, vacuum cup, magnetic, etc.) enable multi-line handling and adaptation to various product types, enhancing system flexibility.

Unlike conventional palletizing machines, robotic palletizing solutions:

- Easily adapt to any workspace

Robots are programmable and configured to avoid obstacles like support columns, optimizing factory space. - Operate in extreme conditions

Robots function reliably even in freezing environments below -30˚C, making them ideal for refrigerated storage. - Maximize stacking capabilities

Robots efficiently stack pallets up to 3 meters tall, optimizing storage.

Comprehensive Robotic Palletizing Solutions

A fully automated palletizing system consists of:

- Robotic Arm & Gripper Set

Designed for precise, high-speed palletizing. - Product Conveyor Belts

Ensuring seamless product transport. - Automatic Pallet Feeder

Increasing speed and efficiency. - Ready Pallet Roller Conveyors

Facilitating quick movement of completed pallets. - Pallet Transport Wagon

Designed for large-scale areas. - Automatic Pallet Wrapper & Strapping Machine

Securing stable, transport-ready pallets. - Safety Fence

Protecting personnel in automated environments.

The Advantages of Robotic Palletizing

Modern manufacturing units worldwide rely on robotic palletizing, benefiting from:

24/7 uninterrupted production

Maximizing output.Reduced production costs

Automating multiple lines with minimal personnel involvement.Higher production speed

Robots accelerate palletizing processes, increasing efficiency.Handling heavy loads beyond human capabilities

Ensuring safe and efficient operations.Optimized space utilization

Robots minimize floor space usage, enabling direct warehouse integration.Operation in harsh environments

Reliable even in extreme conditions.Offline programming

New products can be programmed without production downtime.

Revolutionizing Palletizing with Robotics

With intelligent automation, Gizelis Robotics provides high-performance robotic palletizing solutions tailored to modern industrial demands.

Enhancing Packaging Efficiency with Robotic Automation

Enhancing Packaging Efficiency with Robotic Automation

The packaging and food industries have long embraced robotic automation to improve speed, precision, and cost efficiency. Robotic systems can be integrated across all production lines, handling various packaging formats such as carton boxes, plastic containers, special configurations, and film wrapping.

These systems optimize product placement, reduce production costs, and ensure consistent quality, making them an essential asset in modern manufacturing.

Advanced Robotics for Packaging Automation

Gizelis Robotics provides cutting-edge robotic packaging solutions designed to handle complex and sensitive packaging operations with maximum flexibility and efficiency.

Key Features of Robotic Packaging Systems

- High-Speed Operation with IP 67 Protection

- Robots operate at top speeds, with IP 67-rated models offering full protection against dust ingress and resistance to immersion and water penetration.

- Hygienic Design for Food Safety

- Smooth robotic surfaces prevent bacteria buildup, and through-the-arm cabling ensures problem-free transfer of signals and air. These robots also use food-grade grease in their spindle reducers for safe food handling.

- Smart Camera-Based Analysis

- Automated inspection and orientation detection of sensitive products ensure quality control and system flexibility.

- Seamless Conveyor Belt Coordination

- Robots can synchronize with moving conveyor belts, allowing for continuous operation without stops, significantly boosting production line speed.

- Integration with Packaging Machinery

- Robotic systems work seamlessly with carton sealers, film wrapping machines, and other packaging equipment, ensuring maximum operational flexibility.

- Dual-Function Capability

- When line speeds are low, packaging robots can also handle palletizing, reducing additional production costs.

Why the Packaging Industry Relies on Robotics

With versatile automation capabilities, robotic packaging systems deliver:

- Precise product placement for superior packaging quality.

- Seamless integration into any production line.

- Hygienic and contamination-free handling for food and pharmaceutical applications.

- Cost-efficient operations that reduce manual labor and downtime.

- Flexible configurations that adapt to multiple packaging formats and machinery.

Transforming Packaging with Robotic Automation

Gizelis Robotics delivers state-of-the-art robotic packaging solutions that enhance speed, precision, and efficiency across industries.

Precision and Automation in Assembly Processes

Precision and Automation in Assembly Processes

Assembly is a complex and traditionally human-driven process, requiring precision and adaptability. However, with technological advancements and industrial automation, robotic arms have become an essential part of modern assembly lines, offering increased efficiency, accuracy, and consistency.

The Role of Robotics in Assembly

Robotic systems are revolutionizing assembly operations, handling intricate component assembly with speed and precision. These robots enhance production efficiency, reducing manual workload and ensuring uniform quality across all assembled products.

Selecting the Right Robotic System

The choice of a robotic assembly system depends on several factors, including:

- System Speed

- Ensuring optimized cycle times for maximum productivity.

- Component Weight

- Handling various materials with precision and consistency.

- Operating Radius

- Adapting to different assembly line layouts and space constraints.

Enhancing Assembly with Robotics

By integrating advanced robotic assembly solutions, Gizelis Robotics helps manufacturers streamline production, reduce errors, and boost overall output.

Precision and Flexibility in Robotic Cutting

Precision and Flexibility in Robotic Cutting

Cutting is a high-precision process that demands both accuracy and flexibility. This is especially critical in 3D cutting, where robotic arms excel due to their ability to move freely regardless of tool orientation. By integrating advanced cutting tools such as LASER, PLASMA, WATERJET, and ROUTER, robotic systems follow precise cutting paths, delivering exceptional results with consistency.

Advanced Features of Robotic Cutting

Gizelis Robotics offers cutting-edge robotic solutions designed for automated precision cutting, featuring:

- Seamless Cutting Path Execution

- Robots precisely follow the cutting path, ensuring flawless results.

- Flexible Tool Integration

- Supports various cutting technologies (LASER, PLASMA, WATERJET, ROUTER) for versatile applications.

- Automated Programming Software

- Generates robot source code automatically by processing a 3D sketch with cutting points.

- Smart Sensor Integration

- Maintains optimal cutting distance, detects differences between a piece and its sketch, and calculates the best cutting solution based on tolerances.

Optimizing Cutting Operations with Robotics

With intelligent automation, Gizelis Robotics provides high-precision robotic cutting solutions tailored to complex industrial requirements.

Enhancing Safety and Precision in Press-Braking with Robotics

Enhancing Safety and Precision in Press-Braking with Robotics

Press-braking is a widely adopted robotic application, offering precision, consistency, and workplace safety. Automating rolling procedures eliminates variability in end products and reduces the risk of workplace accidents, making robotic bending an essential solution for modern manufacturing.

The Robotic Bending Process

The automated bending process follows a structured workflow to ensure accuracy and efficiency:

- Sheet Placement & Preparation

- An operator positions a sheet pallet in the feeding area, which features:

- Stops for pallet centering.

- Magnetic spacers to prevent sheets from sticking due to moisture or oil, ensuring smooth operation.

- An operator positions a sheet pallet in the feeding area, which features:

- Robotic Handling & Forming

- The operator activates the system, signaling the presence of new sheets and selecting the relevant program.

- The robot moves to the feeding area, detects sheet height, and securely grips the first sheet.

- If an ice detector is installed, the system verifies that only one sheet is being processed before transferring it to the sliding table saw for precise positioning.

- The robot and the press-brake work together to bend the sheet into the desired shape.

- Final Palletizing & Storage

- Once formed, finished sheets are palletized in a designated storage area, and the process repeats seamlessly.

Advanced Features of Robotic Bending Systems

Gizelis Robotics provides state-of-the-art robotic bending solutions, equipped with:

- Press-Brake Software for Automated Rolling

- Simplifies programming with preloaded routines, allowing modifications without advanced programming knowledge.

- Path Tracking for Consistency

- Robots precisely follow the bending path, ensuring uniform product quality.

- Integrated Palletizing

- The system includes preset designs for organizing completed sheets, ensuring safe and efficient material handling.

- Custom-Designed Grippers

- Vacuum cups or magnetic grippers ensure a secure hold, even for sheets with holes.

- Special gripper designs prevent interference with the press-brake or robot operations.

Transforming Bending Operations with Robotics

By integrating advanced robotic bending solutions, Gizelis Robotics enhances manufacturing precision, safety, and efficiency, ensuring seamless automation in press-braking applications.

Precision and Safety in Robotic Grinding & Polishing

Precision and Safety in Robotic Grinding & Polishing

Grinding is a challenging and hazardous process when performed manually. Maintaining product consistency is difficult, and workers face serious health risks due to exposure to fine particles and potential injuries from close proximity to grinding machines.

Robotic systems provide a safer, more precise, and highly efficient alternative, ensuring flawless quality and consistency in grinding and polishing applications.

The Robotic Grinding & Polishing Process

A closed robotic cell is typically used to contain particles, ensuring a controlled and clean working environment. The robotic system follows a structured process:

- Piece Handling & Processing

- The robot picks the piece from the feeding area.

- It precisely moves the component through all grinding and polishing stages.

- Dust & Particle Containment

- A suction system is installed to maintain a clean robotic cell, depending on the product being processed.

- Final Placement & Repeat Cycle

- Once the process is complete, the robot places the finished product in the discharge area before starting the next cycle.

Key Benefits of Robotic Grinding & Polishing

- Flawless Quality & Consistency

- Robots maintain precision and uniformity, eliminating variations in product quality.

- Maximum Safety for Workers

- Removes exposure to fine particles and hazardous grinding operations.

- Increased Production Speed

- Significantly reduces processing time compared to manual methods.

- Enclosed Robotic Cells for Clean Operation

- Prevents dust dispersion, creating a safe and efficient workspace.

- Competitive Edge

- Companies using robotic grinding and polishing stand out by delivering high-quality products at lower production costs.

Revolutionizing Grinding & Polishing with Robotics

With advanced robotic grinding and polishing solutions, Gizelis Robotics ensures precision, efficiency, and workplace safety, helping manufacturers optimize production while reducing operational risks.

Precision and Efficiency in Robotic Painting & Spraying

Precision and Efficiency in Robotic Painting & Spraying

Robotic automation is the ideal solution for painting and coating applications, ensuring uniform quality, reduced waste, and increased efficiency.

MOTOMAN robotic systems excel in spraying solvent-based paints, whether applied with or without high voltage, delivering consistent and flawless results.

The Advantages of Robotic Painting & Spraying

Automated robotic painting offers precision, speed, and control, optimizing the entire coating process:

- Reproducible Quality

- In a controlled automated cell, robots maintain consistent temperature and humidity, ensuring uniform coating results.

- High-Speed & Accuracy

- MOTOMAN robotic systems execute precise, well-coordinated movements, reducing processing time and eliminating unnecessary waste.

- Maximum Efficiency

- Paint is applied at optimal speed with perfect consistency, guaranteeing a flawless finish every time.

- Tailored Robotic Solutions

- The MOTOMAN EPX series provides a range of customized painting robots, designed to meet specific production needs.

Key Benefits of Robotic Painting & Spraying

- Improved & Consistent Quality

- Uniform application ensures perfect coating results.

- Cost Savings

- Less paint usage, reducing material costs.

- Reduced Dependence on Manual Labor

- Automation minimizes workforce reliance, optimizing production.

- Enhanced Working Environment

- Robots eliminate manual exposure to hazardous coatings.

Optimizing Painting & Spraying with Robotics

With state-of-the-art robotic painting and spraying solutions, Gizelis Robotics delivers precision, efficiency and cost-effective automation for industrial coating applications.

Advanced Robotic Machining for Versatile Materials

Advanced Robotic Machining for Versatile Materials

Gizelis Robotics delivers turnkey robotic machining solutions for a wide range of materials, including wood, stone, marble, aluminum, and steel.

By integrating precision robotics with CNC technology, we ensure fast, accurate, and efficient machining processes, expanding automation capabilities across industries.

Comprehensive Robotic Machining Systems

A robotic machining cell consists of:

- Industrial Robot

- Performs precise cutting, carving and shaping.

- Spindle

- Ensures high-speed, high-precision material processing.

- Robot CNC CAM Software

- Allows seamless multi-axis robotic programming with rotary tables and linear tracks, similar to a 5-axis NC machine.

- Machining Table

- Provides a stable and secure work surface.

- Automatic Tool Change

- Enables efficient transitions between machining tasks.

- Safety Fence

- Ensures a protected work environment.

Effortless CNC Robotic Programming

By collaborating with highly skilled integrators, Gizelis Robotics offers advanced software solutions that guarantee:

- Fast, accurate and easy multi-axis programming.

- Seamless robotic integration with external axes.

- Optimized automation for complex machining operations.

Live Demonstrations for Customers

We offer the unique opportunity for customers to bring their parts for live demos, showcasing the capabilities of our robotic machining solutions in real time.

Revolutionizing Machining with Robotics

With state-of-the-art CNC robotic machining solutions, Gizelis Robotics enhances precision, flexibility and production efficiency for manufacturers across various industries.

Questions?

If you have any questions about our products or services, do not hesitate to contact us. Our team of experienced partners, is ready to answer any questions you may have.