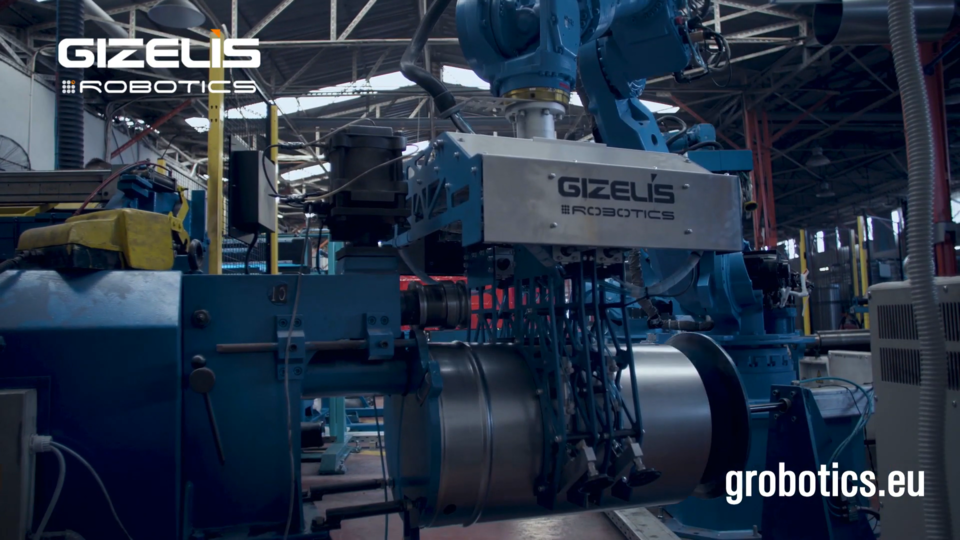

Boiler Line Automation / Calpak Automation

Calpak operates a manufacturing facility for solar water heaters and boilers in Loutraki, Greece. Gizelis Robotics collaborated with Calpak to transform the plant into a smart factory aligned with Industry 4.0 principles. The project included the installation of robotic arms and automation systems for boiler construction, welding, handling, assembly, and an additional production line dedicated to solar panels.

In parallel, the factory was integrated with a private cellular campus network based on 4G and LTE technology and moving towards 5G. This network, implemented by Ericsson and COSMOTE, enables connected robotics, real time data exchange, augmented reality maintenance, IoT applications, and enhanced operational visibility.

Versatile Robotics.

Limitless Possibilities.

Key Features and Components

- Robotic arms and collaborative robots performing welding, heavy part handling, and assembly.

- Integration of data analytics, machine learning, and predictive maintenance systems.

- Real time data collection and algorithm updates for improved uptime and operational efficiency.

- A private wireless network using licensed spectrum that supports mobility, reliability, and flexible production line configuration.

Benefits Achieved

- Improved product quality including enhanced weld consistency and more uniform assembly.

- Increased productivity and throughput with reduced manual labor intensity for repetitive and heavy tasks.

- Improved safety conditions through advanced automation and reduced manual handling.

- Greater flexibility to introduce new product types or adjust production lines due to the automation and connectivity infrastructure.

- Enhanced global competitiveness through advanced manufacturing technologies.

Considerations

- Specific metrics such as percentage improvements in productivity or return on investment are not publicly available.

- The adoption of such systems requires initial investment in robotic equipment, network infrastructure, software, and personnel training.

- Maintenance, cybersecurity, and system integration must be considered carefully and require ongoing management.

- Flexibility should be evaluated regarding the ease of adapting or reprogramming robots when product specifications change.

- Human factors play an important role and require training, change management, and new workflow design

Significance and Context

The project is described as the first smart factory of its kind in Greece using a private cellular campus network for manufacturing. It demonstrates how small and medium sized manufacturers can adopt advanced automation technologies such as robotics, private networks, IoT systems, and augmented reality tools.

The seamless integration of automation and connectivity shows how Industry 4.0 principles are being applied in real industrial environments in Greece rather than remaining theoretical concepts.