Robobend — Robotic Automation for Bending

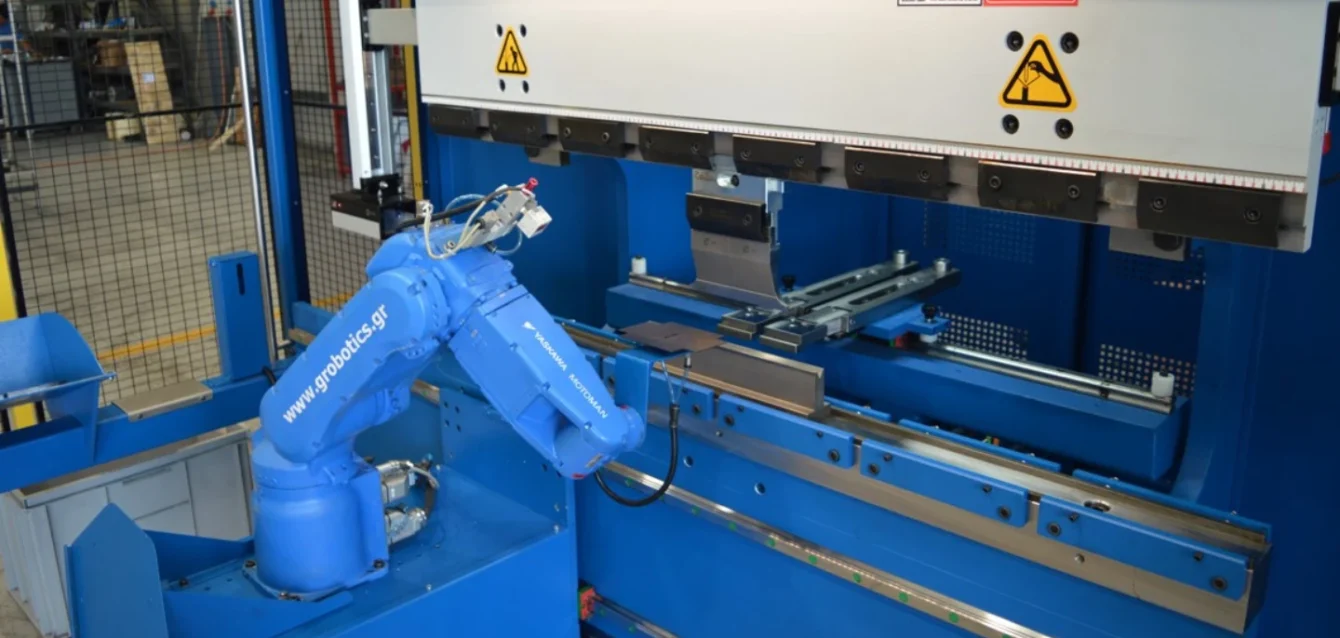

RoboBend is the combination of a Pressbrake produced from Boschert Gizelis and a Robot installed from Gizelis Robotics.

What is remarkable in this machine is the ability for easy manual work from an operator for small batches as he can work freely in front of the Pressbrake because the Linear track is installed directly on the machine making the area free of obstacles.

When large batch production is made the robot can handle its tasks working 24/7. The linear track is an external axis of the robot making accurate and fast moves. The system can also be programmed from offline software, resulting in a small programming time.

This system can be installed to all new Pressbrake we produce.

Key Advantages of Robobend™

Dual-Mode Operation

- Switch instantly between manual and robotic bending.

Maximum Productivity

- Continuous, unattended operation with precise cycle-time synchronization.

High Accuracy

- Robotic handling ensures consistent, repeatable results with minimal scrap.

Safety & Ergonomics

- Reduced manual handling and improved operator safety.

Safety & Ergonomics

- Compatible with a wide range of press brakes and tooling configurations.

Versatile Robotics.

Limitless Possibilities.

Application Uses

Ideal for industries that demand precision and flexibility such as HVAC, enclosures, construction, and general sheet-metal fabrication — Gizelis Robotics automation for bending offers a reliable path toward smart, lights-out manufacturing.

RoboBend is the combination of a Pressbrake produced from Boschert Gizelis and a Robot installed from Gizelis Robotics.

See Robobend in Action

Discover how Gizelis Robotics transforms bending into a fully automated, intelligent process —combining Greek engineering excellence with world-class robotic innovation.